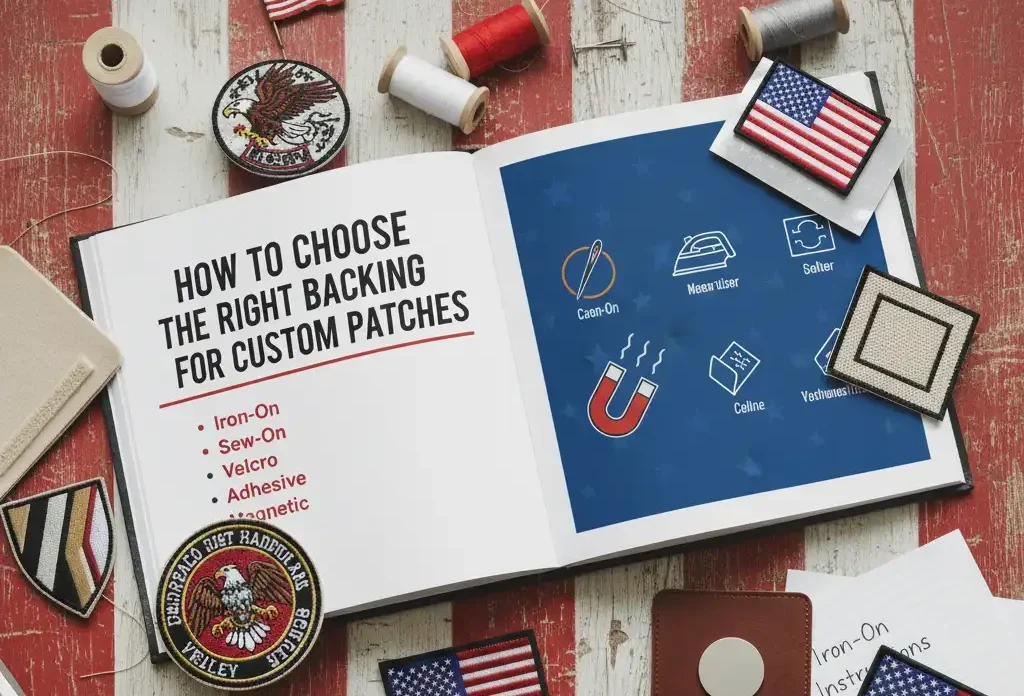

When it comes to custom patches, most people focus on design, size, and colors — but one small detail makes a huge difference: The backing.

The right backing determines how your patch will look, feel, and stay attached. At Custom Patchers, after crafting over 20,000+ custom patches in USA, we’ve seen how the correct backing type can make your patch last for years instead of months.

If you’re wondering which option suits your purpose best, here’s a simple, expert guide to understanding all the custom patch backing types and how to choose the right one.

What Is Patch Backing and Why Does It Matter?

Patch backing is the layer behind your custom patch that helps it attach to clothing, bags, or gear.

Each type serves a different purpose — some are permanent, others removable, and some are best for heavy-duty use.

Choosing wisely matters because it affects:

- Durability – how long it stays attached

- Ease of use – iron-on vs sew-on effort

- Appearance – how flat and clean it looks

Pro insight: Always decide where the patch will be placed (uniform, hat, jacket, etc.) before selecting the backing.

1. Iron-On Patch Backing

Best for: Casual clothing, denim jackets, caps

Iron-on backing comes with a heat-activated adhesive that bonds easily when you press it with an iron or heat press.

Pros:

- Quick and simple to apply

- Clean look without visible stitching

- Ideal for personal and fashion use

Cons:

- The adhesive can loosen after frequent washing

- Not great for heavy or flexible fabrics

💡 If you want an easy, no-sew patch for light use — iron-on is your best friend.

Top Notch and Affordable Patches at One Place!

Get premium-quality patches tailored to your needs—free quotes, fast delivery, and guaranteed craftsmanship.

2. Sew-On Patch Backing

Best for: Military uniforms, outdoor gear, work apparel

Sew-on patch backings are the classic and most reliable option. They require stitching around the patch edge, ensuring it never falls off.

Pros:

- Long-lasting and machine washable

- Works on any fabric type

- Looks professional and permanent

Cons:

- Needs a bit of effort and sewing tools

- Not removable

💡 For uniforms or heavy-duty wear, sew-on backings are the gold standard.

3. Velcro Patch Backing

Best for: Tactical, military, club, or event patches

Velcro (hook and loop) allows you to attach and remove patches whenever needed. One side is sewn to your garment, the other to the patch itself.

Pros:

- Reusable and flexible

- Perfect for interchangeable patches

- Extremely durable

Cons:

- Slightly thicker

- Hooks can catch delicate fabric

💡 If you swap patches often, Velcro makes your life easier.

4. Adhesive & PVC Patch Backing

Best for: Events, giveaways, branding promos

Adhesive (peel-and-stick) or PVC patch backings are made for short-term use. They’re great for temporary applications where quick setup matters more than durability.

Pros:

- Super easy to apply

- Ideal for marketing or trial use

Cons:

- Limited life span

- Not suitable for washing or outdoor wear

💡 If you’re running a one-time event, adhesive backings are cost-effective and simple.

Which Backing Type Should You Choose?

| Purpose | Recommended Backing |

|---|---|

| Casual fashion & denim | Iron-On |

| Military / work uniforms | Sew-On |

| Tactical gear / club patches | Velcro |

| Promotional giveaways | Adhesive / PVC |

| Custom hats & caps | Sew-On or Velcro |

Get a free quote now and let us give you the best option for your patch.

Expert note: Based on thousands of customer orders, Velcro and Sew-On backings deliver the longest life and best appearance overall.

Final Thoughts

The right custom patch backing can completely change how your design performs and looks. Iron-on makes fashion patches quick and easy, sew-on lasts the longest, Velcro gives flexibility, and adhesive saves time for events.

At Custom Patchers, we offer every major backing option — iron-on, sew-on, Velcro, PVC, and adhesive — customized to your design and use case.

Our team ensures each patch is tested for durability, comfort, and color accuracy.

Frequently Asked Questions (FAQs)

1. What is the most durable backing for custom patches?

Answer: The most durable option is sew-on backing because it uses direct stitching instead of adhesive. It can handle repeated washing and heavy-duty wear, which makes it perfect for uniforms and outdoor gear.

2. Which backing is best for easy application?

Answer: If you want a quick and simple method, go with iron-on patch backing. It only needs a household iron or heat press — no sewing required.

3. Can Velcro-backed patches be washed?

Answer: Yes, but with care. Remove the Velcro patch before washing the garment to prevent the hook side from damaging other fabrics. Reattach it once the clothing is dry.

4. What is the difference between iron-on and adhesive backings?

Answer: Iron-on patches use heat-activated glue that bonds permanently with fabric. Adhesive patches, on the other hand, are peel-and-stick — meant for short-term use like events or temporary branding.

5. How do I know which backing type is right for me?

Answer: It depends on your purpose. For fashion and casual wear, use iron-on; for uniforms, go with sew-on; for removable patches, choose Velcro; and for events, adhesive or PVC works best.